Edward, Isle of Skye – A DIY Hot Tub with a View.

Edward got in touch as he was currently in the process of building a new holiday let property and wanted to incorporate a hot tub.

With his builders already on site, he knew that it would be a much cheaper option for him and his team to build the tub rather than getting a spa builder in.

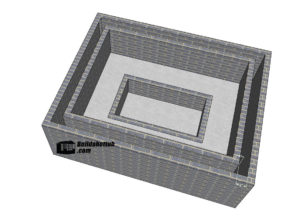

Edward already had the tub planned on his design for his property, as you can see above. The tub is just the perfect addition to the ultra modern design of his future holiday let.

The Plan

To get things moving, Edward purchased the 3.05m x 3.05m with the structural and architectural drawings. Purchasing one of the “stock” designs that you can modify yourself is a much more cost-effective approach than having me do a custom design for you. Not that I want to talk myself out of work, I just like to add value and save you as much money as possible on the way!

With the design in hand, Edward and his team would be able to get cracking on the build.

The initial discussions that we had centred around whether it would be viable to heat with an electric heater. In the end, Edward decided that an Air Source would make much more sense and he went with the Comfortline range which is the same model that I have on my own tub and have reviewed on this blog.

At this stage, Edward’s primary concern was the noise from the Air Source. Although he plans to live in his property for the first year or so, this will be a holiday let. The last thing he wanted was a noisy heater outside the bedroom! The Comfortline is quite a quiet heater but we decided that we would move the pump to a different location that was not underneath the window!

The Location

With the plans in place, Edward ordered all the parts from me and I shipped them up to the Isle of Skye. For those of you that don’t know where this is, it is a small island located off the west coast of Scotland. The views are amazing and this was one of the reasons that Edward wanted to build the tub. Just check out the view below!

This was going to be the location for the hot tub.

Edward’s property is in the grounds of his hotel, the Cuillin Hills Hotel. Here is a link to the hotel for more information – https://www.cuillinhills-hotel-skye.co.uk – it looks absolutely stunning! If you are in the area, definitely the place to stay!

One of the main concerns for Edward was that the walls were not going to be too thick. Aesthetically, he wanted the tub to fit with the ultra-modern design of his holiday let property.

The construction method that Edward has opted for is a hybrid of block and poured form. Whilst it is possible to do either or, what Edward has done is use the block for the interior walls and the seats, then for the exterior, to cover up the plumbing he is going to shutter (form) and then pour concrete.

Not only will this give him the structural integrity that is needed for the tub, it will keep the wall thickness down too.

First steps for Edward were to get the interior walls in place. Then, he was going to fit them plumbing and insulation to these.

Edward and his team fitted all the plumbing to the exterior of the block walls. The next step for them would be to put in the shuttering or wooden forms so that he could pour concrete and cover up the pipework.

Forming and shuttering any DIY Hot Tub is a big job. Whilst it is possible to mix the concrete yourself, if you do this, you find that you have very distinct “layers” as it is of course difficult to mix the exact same mix every time. It is much easier to have it delivered.

When you are ordering concrete, you want to ask for 4000 PSI and add fibres and water proofing agents if this is an option for you – just adds to the quality of the final product. When you do get the concrete delivered, you want to have plenty of “hands on deck” to get the concrete poured and vibrated down.

If you don’t offload your concrete in a reasonable time, you will definitely be charged as the delivery driver will be making a number of timed stops – something to bear in mind if you haven’t ordered concrete before.

You can see in the images that there is a large amount of bracing on the forms. Concrete is heavy and the last thing you want is for the walls to bow under the weight before it has even dried.

The next step is of course to let the concrete cure. You don’t want to be removing those forms until you are certain that your concrete is pretty dry. If you are in a warmer climate, don’t let you concrete dry out too quickly as it will crack. Cracks equal leaks so something to bear in mind.

Fast forward a couple of days and wow – Edward’s DIY Hot Tub is really taking shape. How good does this look? And that view……

It was all going so well….

Edward’s build was progressing at a rate of knots. Him and the team were really putting this together at pace.

It came to time of testing, ignoring a couple of air locks which is part of the course, the systems were all up and running.

The air source was heating. The jets were all nice and bubble – but there was a leak.

Edward was loosing around 10″ / 25cm of water overnight!

That is quite a large leak. With it being during the winter, this made it even harder to trace the culprit as there was water all over the ground anyway.

The fact that the water was levelling out around the jets was indicative. It was pointing to either the plumbing or the jets housings. Edward resorted to tracer dye and was testing around all of the jets with the physical jets removed.

He found the culprit, there was a bad seal around one of the jets and this was causing the leak. He sealed it up with some epoxy putty and bingo! the leak was fixed and the water was holding.

Job Done! What a View!

The final pictures that Edward has sent me on this build are just stunning. This view and this hot tub are just simply spectacular.

Once again, another “hot tub student” flies away from the preverbal ‘hot tub nest”

One very proud teacher here – this is just a fantastic build – well done Edward!

Can I Help You?

If I can help you in any way I would love to hear from you. You can get in touch using the form below.

Thanks - Andi

Hi, Andi here. I own Buildahottub.com and also write all of the articles and info pages on the site. Some years back now, I built my own hot tub but struggled to find the information I needed. So, once my tub was complete, I started this website to help others in their own pursuit of hot tub and plunge pools DIY building information.

Hi, Andi here. I own Buildahottub.com and also write all of the articles and info pages on the site. Some years back now, I built my own hot tub but struggled to find the information I needed. So, once my tub was complete, I started this website to help others in their own pursuit of hot tub and plunge pools DIY building information.

Fast forward to 2025, I've helped over 1400+ DIY customers just like you all over the world build hot tubs and pools. Have a good look around the site, there are lots of resources here. Please do get in touch if I can help you. - Cheers, Andi